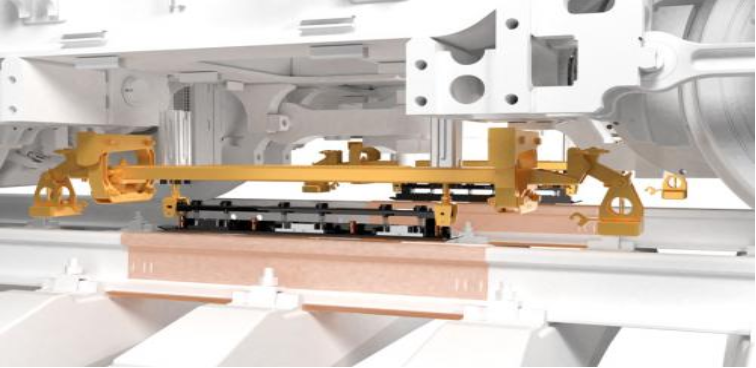

UT140 Flaw Detection System

UT140 is used to detect rail damage by ultrasonic nondestructive flaw detection. With the sliding boots structure the flaw detection system can adapt to the bad environment. The speet could reach 140km/h.

Magnetic alignment is adopted in the flaw detection system to ensure that the whole flaw detection module is in the correct position above the rail.

The unique undercarriage structure design enables the flaw detection system to be installed under the special flaw detection bogie as well as on most standard out-of-shape bogies or car bodies.

There is only a protective film and water coupling liquid between the ultrasonic sensor and the rail. This design allows ultrasonic waves to reach rail surfaces more quickly, so that the sensor could get the multiple ultrasonic echoes, increase the accuracy of flaw detection

The flaw detection system adopts modular design with low maintenance cost. In normal use, only the protective film is fragile and consumable, and the overall maintenance cost of the flaw detection system is less than half of the existing detection wheel type.

Previous: UT70 Flaw Detection System

Next: None